Discover how 3D drawing revolutionizes the door handle industry

? Discover how 3D drawing revolutionizes the door handle industry?

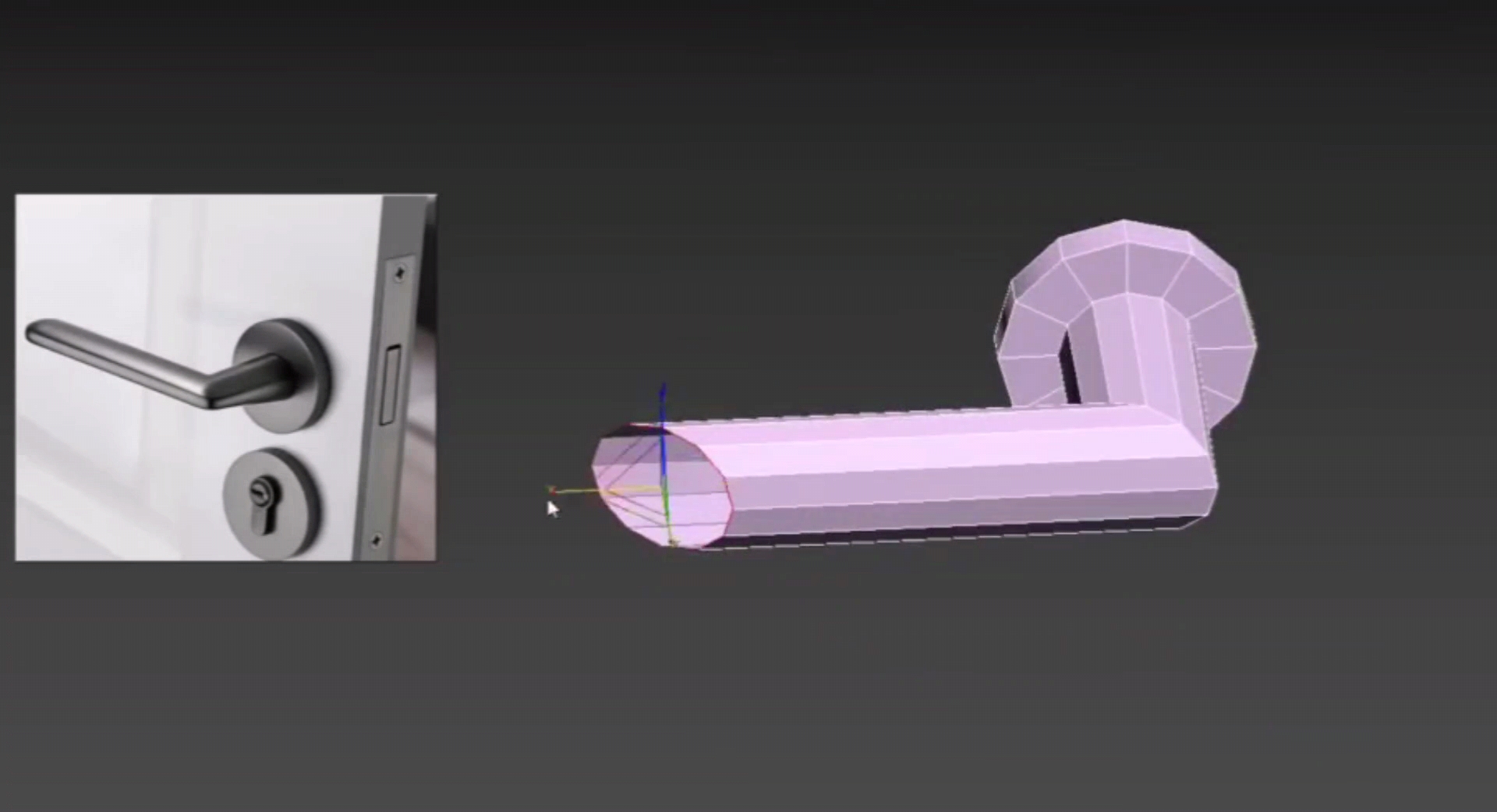

The door handle industry is transforming, thanks to the integration of 3D drawing technology. This innovative approach to design and manufacturing has the potential to revolutionize the way door handles are conceptualized, created, and utilized. The impact of 3D drawing on the door handle industry is far-reaching, influencing design aesthetics, customization options, production efficiency, and ergonomic functionality.

One of the most significant impacts of 3D drawing on the door handle industry is the ability to create intricate and customizable designs. Traditional manufacturing methods often limit the complexity and customization of door handle designs. However, with 3D drawing, manufacturers can explore a wide range of shapes, textures, and patterns, resulting in door handles that are not only visually appealing but also tailored to specific architectural styles and individual preferences.

Furthermore, 3D drawing technology enables door handle manufacturers to streamline the prototyping and production process. By using 3D drawing software and additive manufacturing techniques, designers can rapidly iterate on concepts and produce physical prototypes with greater speed and precision. This accelerated development cycle allows for more efficient testing of design variations and the exploration of innovative concepts that were previously impractical to implement.

In addition to aesthetic considerations, 3D drawing has the potential to enhance the ergonomic functionality of door handles. Designers can leverage 3D drawing technology to create handles with advanced ergonomic features, improving user comfort and usability. This includes the ability to tailor handle shapes and sizes to specific user needs, as well as integrating innovative grip patterns and tactile elements for enhanced functionality.

Moreover, 3D drawing technology opens up new possibilities for material selection and production techniques in the door handle industry. Manufacturers can experiment with a diverse range of materials, including advanced polymers and metal alloys, to achieve the desired aesthetic and functional properties. Additive manufacturing processes such as 3D printing offer greater flexibility in material usage and allow for the creation of complex geometries that were previously challenging to produce using traditional methods.

The impact of 3D drawing on the door handle industry extends beyond the design and production phases. It also influences consumer engagement and market dynamics. With the ability to offer customized door handle designs, manufacturers can cater to niche markets and address specific architectural or interior design requirements. This personalized approach has the potential to create new opportunities for differentiation and market positioning within the industry.

In conclusion, 3D drawing technology is reshaping the door handle industry by enabling the creation of intricate, customizable designs, streamlining production processes, enhancing ergonomic functionality, and expanding material possibilities. As this technology continues to evolve, it is expected to drive further innovation in door handle design and manufacturing, ultimately shaping the future of this essential architectural component.

The integration of 3D drawing in the door handle industry represents a paradigm shift that holds promise for both manufacturers and consumers alike. As designers and engineers continue to push the boundaries of what is possible with 3D drawing technology, we can anticipate a new era of door handle design characterized by creativity, functionality, and personalized expression.

------------------------- ☞Contact us for more stainless steel door hardware Website: www.hengly.com Email: sales@hengly.com | annie@hengly.com Phone: 86-750-3961518 | 86-13631803967