Guides to DIN EN 1906 – European and German standardization for hardware - door handles and knobs

For the purposes of European standardization, EN 1906 has been worked out to specify the requirements and test methods for door handles and knobs. It was implemented as a European standard in October 2001. After several revisions, it is currently valid as EN 1906:2012.

The DIN EN 1906 only defines performance parameters while the dimensions of the hardware are not taken into account. It introduces a classification code system, allowing products to be compared. This European Standard specifies test methods and requirements for spindle and fastening elements, operating torques, permissible free play and safety, free angular movement and misalignment durability, static strength, and corrosion resistance for sprung and unsprung handles and knobs for doors on backplates or roses. Requirements and test methods are structured in such a way that everyday use is simulated.

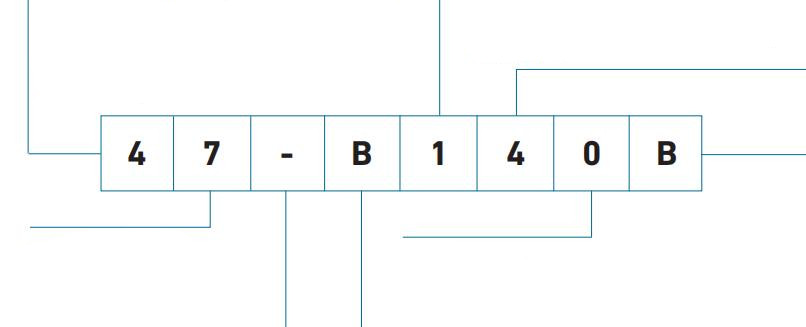

The DIN EN 1906 is classified by an 8-digit code system:

DIGIT 1: Category of use (Grades 1-4)

Grade 1: Medium frequency of use by people with a high incentive to exercise care and with a small chance of misuse, e.g. internal residential doors.

Grade 2: Medium frequency of use by people with some incentive to exercise care but where there is some chance of misuse, e.g. internal office doors.

Grade 3: High frequency of use by the public or others with little incentive to exercise care and with a high chance of misuse, e.g. public office doors.

Grade 4: High frequency of use on doors that are subject to frequent violent usage, e.g. football stadiums, offshore installations (oil rigs), barracks, public toilets, etc.

Digit 2: Durability (Grades 6 or 7)

Grade 6: 100.000 test cycles

Grade 7: 200.000 test cycles

Digit 3 - Door mass

No classification is defined.

Digit 4 - Fire resistance (Grades 0, A, A1, B, B1, C, C1, D, or D1)

Grade 0: Not approved for use on fire/smoke door assemblies

Grade A: Suitable for use on smoke door assemblies

Grade A1:Suitable for use on smoke door assemblies (tested with 200,000 test cycles on a test door)

Grade B: Suitable for use on fire/smoke door assemblies (tested with 200,000 test cycles)

Grade B1:Suitable for use on fire/smoke door assemblies (tested with 200,000 test cycles on a test door)

Grade C: Suitable for use on smoke and fire-resistant doors with requirements; for fire-resistant dividers in the backplate, door rose, and escutcheon

Grade C1:Suitable for use on smoke and fire-resistant doors with requirements for fire-resistant dividers in the backplate, door rose, and escutcheon (tested with 200,000 test cycles on a test door)

Grade D: Suitable for use on fire/smoke door assemblies with require a steel core in the handle

Grade D1: Suitable for use on fire/smoke door assemblies with required a steel core in the handle (tested with 200,000 test cycles on a test door)

Digit 5 - Safety (Grades 0 or 1)

Grade 0: Normal use

Grade 1: Safety applications

The quality for Grade 1: handles must have high-strength handle-to-plate and plate-to-door fixing and/or handle-to Spindle fixing, such that they would withstand a person grabbing in order to prevent falling. It is recommended that only safety furniture be used at the top of cellar steps or other staircases.

Digit 6 - Corrosion resistance (Grades 0-5)

Grade 0: No defined corrosion resistance (no test)

Grade 1: Mild resistance (24-hr salt-spray test)

Grade 2: Moderate resistance (48-hr salt-spray test)

Grade 3: High resistance (96-hr salt-spray test)

Grade 4: Very high resistance (240-hr salt-spray test)

Grade 5: Extremely high resistance to corrosion (480-hour salt-spray test)

Digit 7 - Security (Grades 0-4)

Grade 0: Furniture not approved for use on burglary-resistant doors

Grade 1: Mild burglary resistance

Grade 2: Moderate burglary resistance

Grade 3: High burglary resistance

Grade 4: Very high burglary resistance

Digit 8 - Type of operation (Grades A, B, or U)

Grade A: Spring-assisted furniture

Grade B: Spring-loaded furniture

Grade U: Unsprung furniture